What is IO-Link?

IO-Link is a communication standard in the industry that enables digital interaction between automation and sensor/actuator devices. It provides bidirectional data transmission at the endpoint level, allowing for precise parameterization, monitoring, and remote diagnostics. Due to interface standardization, IO-Link streamlines the integration and configuration of various devices within industrial automation systems.

What devices can be connected via IO-Link?

- Sensors and encoders: IO-Link facilitates precise communication between sensors and controllers, enabling remote configuration, parameter monitoring, and rapid diagnostics. This is particularly crucial in precise manufacturing processes where accurate sensor data is essential.

- Actuators and valves: For actuators such as solenoid valves or servo drives, IO-Link allows flexible control and parameter monitoring, optimizing control processes. Remote configuration simplifies the integration of different actuators in a unified network.

- Vision systems: In image processing applications, such as vision cameras, IO-Link can be used to transmit configuration data and receive feedback on image quality, enabling quick responses to changing production conditions.

- Level and humidity sensors: In industries where monitoring substance levels or humidity is crucial, IO-Link enables precise adjustment of sensor parameters to changing conditions, maintaining production process stability.

- Industrial robots: In industrial automation, industrial robots often use IO-Link for communication with various tools and sensors, allowing flexible robot configuration for different tasks and quick adaptation to variable working conditions.

What are the major advantages of using IO-Link in industry?

Using IO-Link in industry offers several benefits, including:

1. Configuration flexibility: IO-Link allows remote configuration and parameterization of devices, enabling quick adaptation to changing production conditions without physical intervention.

2. Bidirectional communication: This standard enables bidirectional data transmission between devices and controllers, facilitating parameter monitoring, remote diagnostics, and production process optimization.

3. Increased precision: IO-Link enables precise adjustment of sensor and actuator parameters, resulting in increased measurement and control precision, particularly crucial in precise applications.

4. Rapid fault identification: The system allows quick identification and localization of faults through remote diagnostics, reducing downtime and increasing machine availability.

5. Interface standardization: IO-Link provides a unified communication interface, simplifying the integration of diverse devices into one system. This, in turn, simplifies the installation, maintenance, and expansion of industrial systems.

6. Reduction in installation and maintenance costs: With the ability for remote configuration and diagnostics, IO-Link contributes to lowering costs associated with the installation, maintenance, and upkeep of industrial automation systems.

These advantages make IO-Link an increasingly popular standard in the industry, supporting the efficiency and innovation of production processes.

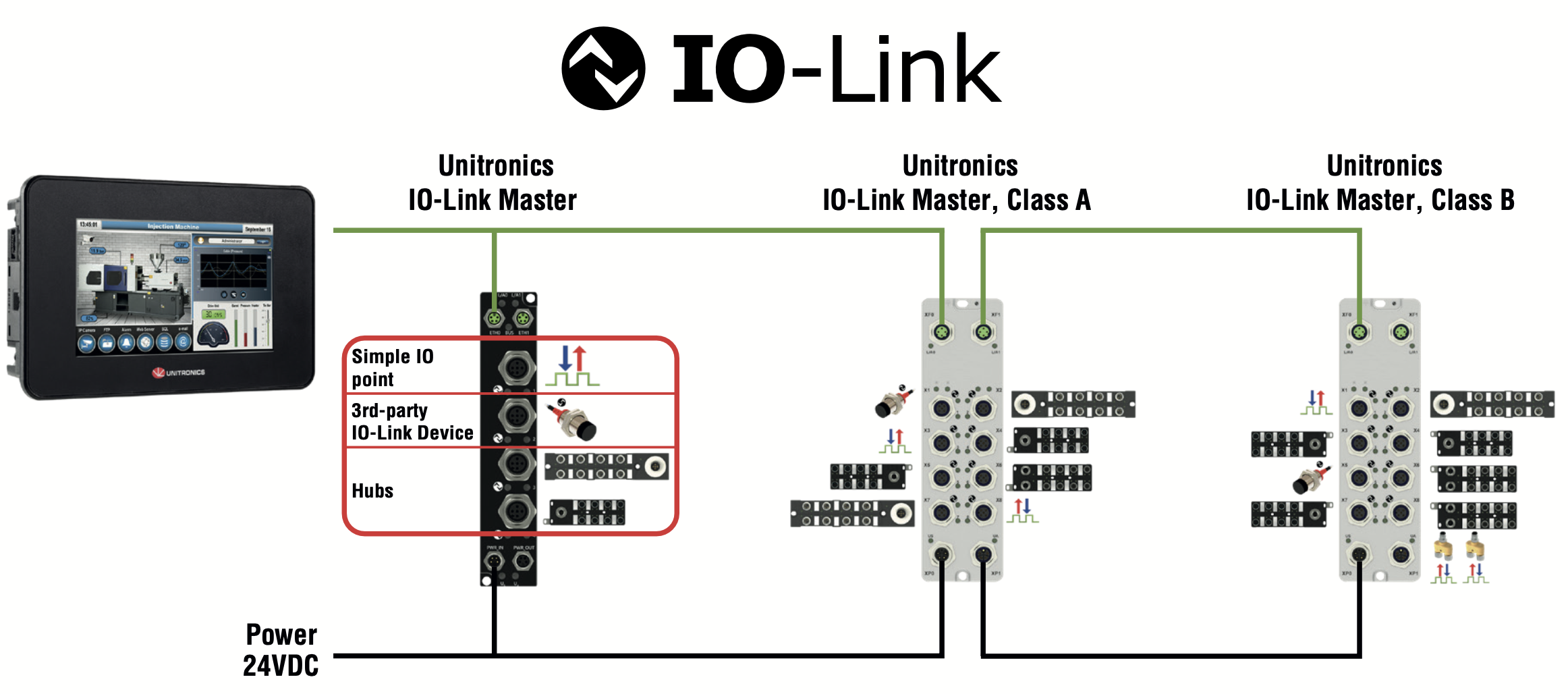

Check out IO-Link Unitronics:

1. IO-Link Master

Unitronics Master modules can:

- Be connected to IO-Link sensors and actuators, which can be configured by importing the IO Device Description (IODD) provided by the device manufacturer.

- Be connected to Unitronics' digital IO-Link hub.

- Have individual ports configured as regular digital IO.

There are two classes of Master modules: Class A and Class B. Class A includes standard IO-Link ports, while Class B ports offer an additional power pin to support devices requiring higher current to operate. Unitronics Master modules are available in different models, differing in the number of ports and the class of offered ports.

2. IO-Link Hub

Unitronics I/O hubs offer 8 or 16 I/O points. Each hub port can be set as a digital input, output, or left unused. In some hubs, a single port can be configured to support two digital I/O devices.

3. Accessories:

- Splitter – for splitting input signals

- Power and signal cables.